You have lots of choice when it comes to companies offering custom gasket creation, and there are also plenty of different methods for cutting those gaskets. So why go with a provider using water jet cutting?

You have lots of choice when it comes to companies offering custom gasket creation, and there are also plenty of different methods for cutting those gaskets. So why go with a provider using water jet cutting?

… because water jet cutting is actually one of the most versatile and cost-effective options available.

Choosing Precision Cutting Service for your gaskets needs could open up new possibilities in materials, as well as helping your bottom line.

Three Reasons to Consider Water Jet Cutting For Gaskets

- Cost Savings

Simply put, water jet cutting is one the least-expensive industrial cutting methods available. It is literally a very small stream of water under extremely high-pressure. That means no high-energy lasers that can burn the material, or expensive dies that can be damaged in through use or in handling.

On top of that, with water jet cutting, there is no need for finishing or touch-up work. The water jet cuts are always smooth and precise. This further reduces production costs, as well as decreasing turnaround time.

- Great Material Selection

Another major benefit to water cutting is that it can be used on virtually any material. You don’t have to worry about the burns and heat deformation that come with laser cutting, or physical saws causing structural damage.

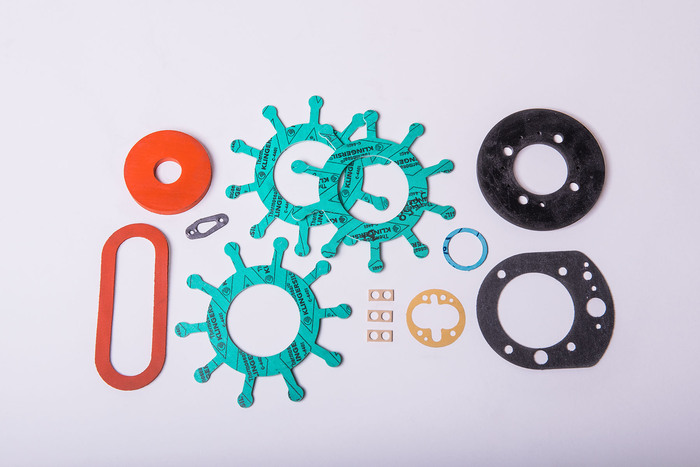

We keep a vast stock of materials on-hand, and we’re happy to work with you to find the best possible material to fit the needs of your project. You’ve got more options with water jet cutting than with other methods – metals, plastics, ceramics, rubbers, polymers, and more.

- Highly Detailed Custom Work

Our machinery is accurate to ±0.003 and can produce gaskets of virtually any thickness up to 2″. Computer-controlled systems allow us to easily create custom gaskets, including gaskets with extremely complex designs that would be expensive to produce with conventional die cutting. And, even this custom work has a short turnaround time.

Precision Cutting Service Offers a Great Cutting Alternative

Water jet cutting is a highly viable and cost-effective solution for commercial gasket cutting, as well as other custom parts creation. Contact Precision Cutting Service today to discuss your next project.