At Precision Cutting Service, we’re proud to offer a range of custom fabrication solutions, including water jet cutting. No matter what size, shape or part you want, our cutting capabilities can handle it. If you are wondering exactly what we can cut, and what the benefits are of this particular type of cutting method, read on. We’ve prepared a quick guide to help clarify what our water jet cutting service can produce.

What Can Be Cut by Water Jet Cutting Systems?

Our water jet systems can easily cut materials up to 6 inches thick and in some cases even thicker. For pipe and tubing splitting and drilling, the largest diameter we can cut is 8 inches and the longest length is 12 feet. The largest size of flat material we can cut is 6’ x 12’, about the size of a full-size SUV, and the smallest is the size of a dime or a little less.

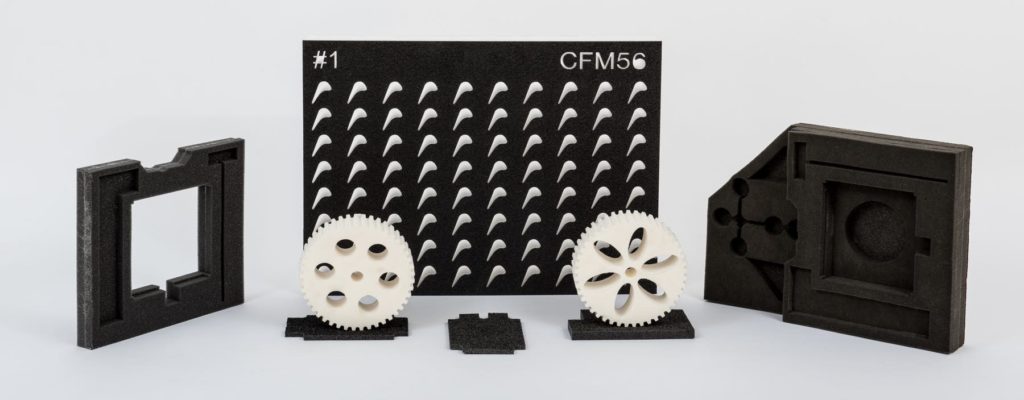

Some of the many materials we cut include:

- Metal—From stainless steel and aluminum to titanium and more, you will get exact, smooth-cut edges that will be free of burn marks (water jet cutting is a cold method).

- Natural Materials—Whether you are looking to cut stone, marble, granite, ceramics, or even glass, our water jet cutting capabilities will get the job done for you.

- Plastics & Composites—Everything from carbon fiber and rubber, to acrylics and foam, can be cut without damaging the material and can be machined to your exact specs.

Amazing Finishing & Machining Capabilities

With our water jet cutting capabilities, we create precise, smooth-edged parts with up to 60,000 psi power and tolerances as tight as ±.003.”To put that power and precision in perspective, residential power washers, with a much thicker steam, normally have about 1,400 to 2,100 psi.

No matter how intricate or elaborate the parts you need are, our water jet cutting systems can produce them, and we are especially adept at metal fabrication and producing custom gaskets, OEM parts, custom signs and custom floor medallions.

An Affordable Service

Costs are kept to a minimum because our water jet systems are computer driven, which minimizes material waste and speeds cutting. In addition, because of our system’s flexibility, we can work with tight deadlines, which could also save you even more money by preventing unplanned downtime.

Get Custom Water Jet Cutting Services Today

Since 1994, we’ve been proudly providing the very best in customized water jet cutting solutions for a wide range of industries, including aerospace, agriculture, transportation, marine, architectural and chemical, to name a few. It doesn’t matter if you have a CAD file, technical drawing, physical part we can reverse engineer, or a simple sketch, we can work with almost anything you provide us.

To learn more about our custom water jet cutting services contact our team today.