The options for producing custom cut gaskets are evolving and waterjet cutting is leading the way. As industries seek more efficient and reliable sealing solutions, the enormous capabilities that waterjet cutting offers solve virtually every gasket need found throughout the US.

As a pioneer in this domain, Precision Cutting Service distinguishes itself by providing state-of-the-art materials and services to meet the varied demands of clients in all industry sectors. This blog explores how they, with their modern waterjet cutting systems, are influencing how gaskets are being produced today and will be in the future.

Waterjet Cutting

This technology is strong, fast, economical and adaptable, and is especially useful for producing gaskets from metals, polymers, rubber, and composites. These sophisticated waterjet cutting systems use programmatic digital front ends and fine, high-pressure streams of water to precisely shape custom or standard gaskets on demand in volumes both large and small. It is perfect for cutting both intricate and straight forward designs that often prove to be challenging for less-flexible technologies.

Precision

A critical requirement for gasket production is precision and repeatability. The waterjet cutting systems that Precision Cutting Service employs dependably cut designs, either as one-offs or as repeat orders, with tolerances as tight as .003,” in thicknesses up to 8” and in sizes as small or smaller than a dime or as large or larger than a full-size SUV. While this flexibility is important for all industries, it is essential for aerospace, medicine and petrochemicals, where a leak or pressure seal failure could cause catastrophic damage, injury or death.

Material Versatility

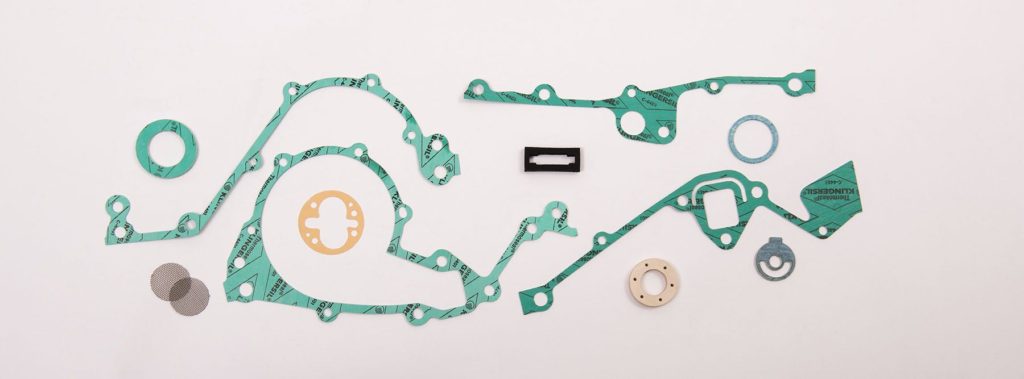

There are any number of materials available for producing dependable gaskets and Precision Cutting Service leads the way in custom cutting them for industries nationwide. Three of the more commonly used materials are:

- Silicone—perfect for gaskets in automotive engines, aircraft fuel lines, and electronic components because of its resilience to heat, chemicals, and UV light.

- Rubber— a great material for gaskets in machinery, various sealing applications, and power transmission systems because of its strength, flexibility, and adaptability.

- Non-asbestos fiber—suitable for gaskets in boilers, furnaces, and other demanding applications. It offers safety, fire resistance, and high-temperature tolerance.

If you are looking for proven gasket solutions, reach out to Precision Cutting Service today. You can use their online contact us form, or their online quote form, or you can simply call 912-233-9550. Our friendly and knowledgeable staff will be delighted to answer your questions and further explain how our waterjet cutting capabilities will help you achieve the results you want.