Waterjet cutting provides precise solutions for a variety of cutting applications, including dimensional signs and letters, marble floor medallions, petro chemical gaskets and all sorts of OEM parts, to name just a few.

Sometimes, depending on the material to be cut, abrasive material may be added to the water to give it more cutting power? For lighter materials, pure waterjet cutting—that is, without abrasives—is often preferred, but, for harder materials like steel, very fine abrasive materials are often added to the water to speed cutting.

As one of today’s leading waterjet cutting services, the team from Precision Cutting Service chooses between pure and abrasive waterjet cutting solutions for each job, depending on that job’s requirement. Below, we’ve collected some insight into how we make the determination.

Pure Waterjet Cutting

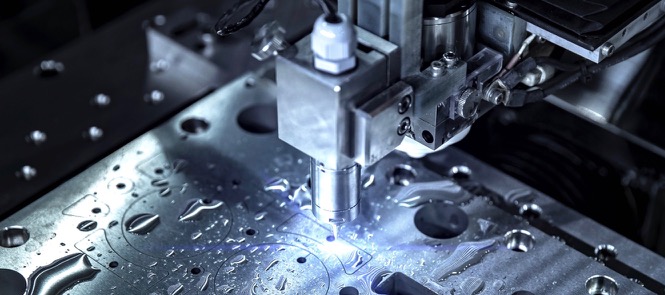

One of the primary differences between pure and abrasive waterjet cutting is that pure waterjet cutting employs a different style of cutting head. There’s no mixing chamber on the nozzle since there’s no abrasive mixture that needs to be pumped through the cutting head.

Abrasive water jet cutting employs a larger cutting nozzle that creates a heavier, more powerful stream. If not careful, the abrasives in the water can deform the edges of softer materials like foam and rubber. However, because almost no pressure is applied to the material being cut—only to the water that is used for cutting—pure waterjet cutting works incredibly well for most materials. It’s as the material to be cut becomes harder that consideration needs to be given to adding abrasives to the cutting stream.

Abrasive Waterjet Cutting

With abrasive waterjet cutting, a specialized pump is employed that pressurizes the water up to 94,000 psi. Coupled with this pump is a mixing chamber that contains and introduces abrasives to the water. The pressurized, abrasive water then passes through a jewel attachment on the cutting head, creating an intense, but very fine, super stream of water that acts like a powerful blade.

Among the more popular abrasives that water jet cutting operations like Precision Cutting Service uses is Almandine garnet because it possess an effective combination availability, particle shape, hardness and cost.

Abrasive waterjet cutting is best used for materials such as:

• Marble and Granite

• Steel and Iron

Abrasive waterjet cutting makes it easy to cut such hard materials and is much less time-consuming, offering a precision, cost savings, and speed that can’t be replicated with other cutting methods.

Contact us for pure and abrasive waterjet cutting services!

If you need efficient and precise waterjet cutting services, contact Precision Cutting Service online today or call (912) 233-9550. We specialize in gaskets, custom cut signs and medallions, metal fabrication and more.