There are a lot of different methods for cutting various materials, and most of the time people think in terms of saws or lasers. However, there’s another versatile and highly effective option that produces amazing results: water jet cutting services, a multi-purpose cutting method that works well with almost any material.

Here’s how it works.

Why Water Jet Cutting Services Are A Great Option for Custom Cutting

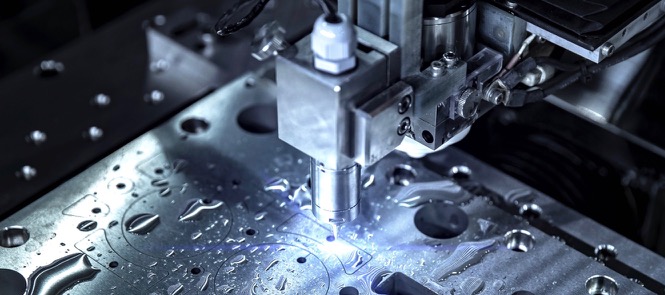

Water jet cutting utilizes a fine stream of water that is incredibly pressurized and forced through a nozzle with a diameter of only around .15mm.

The result functions much like a blade that is capable of smoothly slicing through almost anything. And to boost its cutting power, the water can be seeded with an abrasive like diamond dust. This enables even the hardest materials—up to eight inches thick—to be effectively cut.

It’s very quick and very accurate, capable of achieving tolerances up to ± .003.”

Water jet cutting also brings several other benefits:

- Water jets don’t damage the surrounding material. Lasers or plasma torches can scorch the material, while blades will leave rough edges.

- For this reason, water jets don’t require any rework or finishing. The cut is perfectly smooth on the first pass.

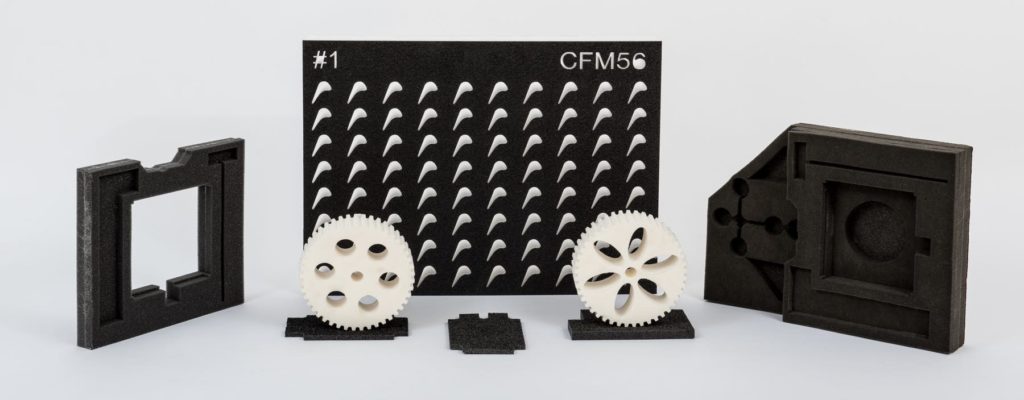

- Water jets can be used on virtually any material, even those too heat-sensitive for lasers or too fragile for blades, and they can even safely cut foam.

In short, water jet cutting services can cut almost anything faster, better, and less expensively than just about any other cutting method.

Precision Cutting Service Can Create the Custom Products You Need

From signs to floor medallions to custom gaskets and OEM parts, our water jet cutting services can be relied on for a huge number of applications. Contact us to learn more!