Waterjet cutting is the fastest-growing cutting technology in the United States because it offers a wide range of benefits. With versatility and accuracy that is second to none, waterjet cutting’s fast programming and production speed helps both companies and individuals affordably achieve the cutting and shaping objectives they seek.

At Precision Cutting Service, we use advanced waterjet cutting machines to create top-quality parts from virtually any material, and in shapes and sizes that range from simple and small to large and complex. Industries throughout the US, including aerospace, transportation, food processing, construction, healthcare, agriculture and more, rely on us every day to cut and fabricate their products, and we can do the same for you.

Precise Cuts

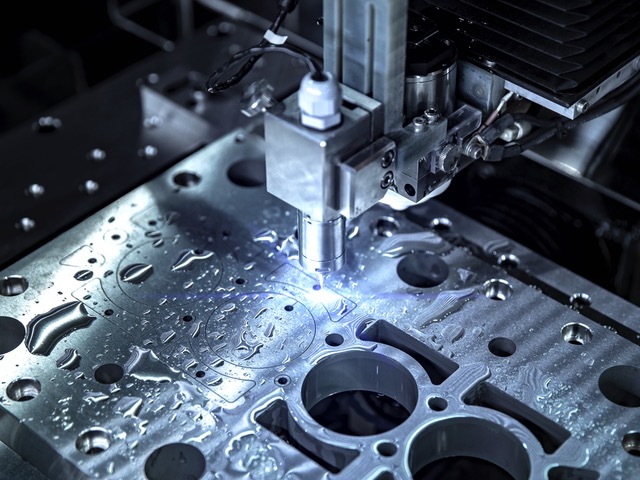

Generating very fine high pressure streams of water that do the cutting, waterjet cutting systems are equipped with computer-driven, robotically controlled cutting nozzles that produce exact, smooth, and burr-free cuts. The resulting superior edge quality is such that post-finishing, like sanding or polishing, is never required. Our state-of-the-art facility in Savannah, Georgia, is equipped with machines operating at pressures up to 60,000 psi, with incredibly tight tolerances of ±.003.”

Dimension Flexibility

Our waterjet cutting machines cut patterns and parts up to 12 feet long, 6 feet wide, and 8 inches thick. They can also cut them as small or smaller than a dime. So, whether you need artwork, custom patterns, logos, or geometrically complex designs, you can depend on waterjet cutting to deliver what you need. Indeed, at Precision Cutting Service, we like to say, “Our only limitation is your imagination.”

Preserving Material Integrity

A cold cutting technology, waterjet cutting never alters the chemical composition of the material it cuts, nor does it scar, burn or rip the material. Manufacturers, in particular, use waterjet cutting for machines that require tightly fitting parts. For the food industry, water jet cutting provides gaskets and other parts that help prevent cross-contamination. Likewise, in aerospace where accuracy is of prime importance, waterjet cutting technology helps teams avoid warping and cracks caused by heat zones that laser cutting and other technologies leave behind.

Give Waterjet Cutting a Try

For more than 28 years, Precision Cutting Service, has cut and fabricated products for hundreds of customers nationwide. Let us do the same from you. We make ideas happen.

Send us your specs via an email, sketch, CAD, PDF, vector file or the actual part you need us to fabricate. Or simply call us to learn more—912-233-9550. Our experienced and friendly customer service representatives will be delighted to walk you through the benefits Precision Cutting Service can add to your operation.