Waterjet cutting systems effortlessly cut stainless steel, aluminum, marble, granite, porcelain, VCT, rubber, plastic and other synthetics, to name a few.

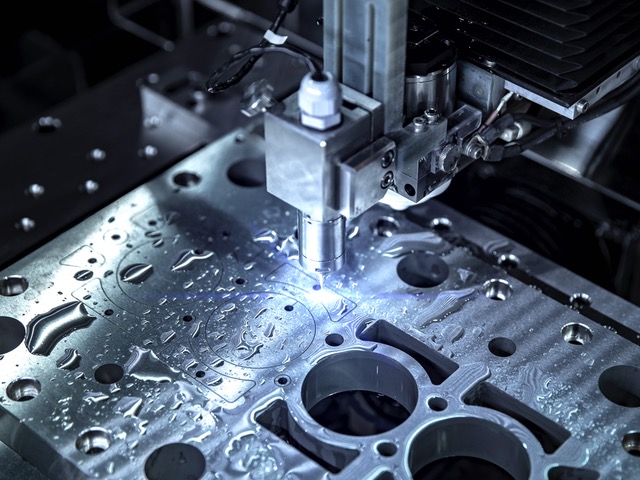

They use a computer controlled, high-speed, high-pressure and very fine stream of water to precisely cut virtually any material for various applications, including auto parts, aerospace components, gaskets, dimensional signs, architectural flooring, kitchen and bathroom backsplashes and more.

The pressurized water shoots through a small-bore nozzle, enabling it to cut tight tolerances up to .003.” It can also be enhanced with abrasives, such as diamond dust, to improve its cutting power. The resulting output is always a precisely cut product with smooth edges that do require secondary finishing.

As a leading waterjet cutting service provider, Precision Cutting Service employs multiple waterjet cutting systems to cut material as large as 6’ x 12’ and as thick as 8.” We also make intricate cuts in pieces as small or smaller than a dime. We produce top-quality gaskets, floor medallions, OEM parts, 3D signs and other products for hundreds of clients nationwide, and we can do the same for you. In short, we are well-equipped to fulfill virtually any cutting requirement efficiently and effectively.

Here’s a quick look at the material our waterjet machines can cut:

Stone

Granite, marble, porcelain and other hard natural materials do not provide a difficult cutting challenge for our water jet cutting systems. Our sophisticated waterjet cutting systems can cut the stone designs you require with relative ease. Floor medallions and kitchen backsplashes tend to be the most popular applications for stone.

Metals

Waterjet cutting is particularly effective for stainless steel, aluminum, iron, titanium and other alloys.

Some cutting methods, such as lasers and plasma devices, can change the chemical composition and properties of metal because of the heat they generate. This can be problematic for applications when maintaining the integrity of the metal is important.

Waterjet cutting, on the other hand, is the superior choice for cutting metals because it is a cold cutting technology that eliminates any possibility of damage to the material being cut. Plus, it is precise, fast and always leaves a smooth edge that does not require sanding or filing after the material has been cut.

Glass

Water jet cutting systems are and excellent choice for cutting glass. Their fine, precise streams of water prevent cracking, chipping or shattering, even when cutting small or complicated pieces. And every cut edge is as smooth as glass, so to speak.

Plastics and Composites

Again, heat-based cutting methods typically burn or melt plastic, making precise, clean cuts impossible. Saw blades can cut plastic but require a lot of post cut finishing, like sanding. In addition, saws are not particularly effective for making small, intricate cuts.

Waterjet cutting solves these issues. It maintains the integrity of the plastic or composite material and produces fast, precise, smooth and affordable cuts for everything from carbon fiber and rubber, to acrylics and foam—all to your exact specifications.

For more than 28 years, Precision Cutting Service has worked with gasket manufacturers, architects, corporate purchasing departments, machine shops, furniture designers and others to produce top quality parts and products. Always ready for assignments large or small, our friendly veteran team offers tailored solutions for your specific needs with responsive service and timely delivery.

Call (912) 233-9550 or email sales@precisioncuttingservice.com to learn more about our comprehensive waterjet cutting services. Alternatively, you can share your requirements online via our request a quote page. Our friendly team will get back to you promptly.