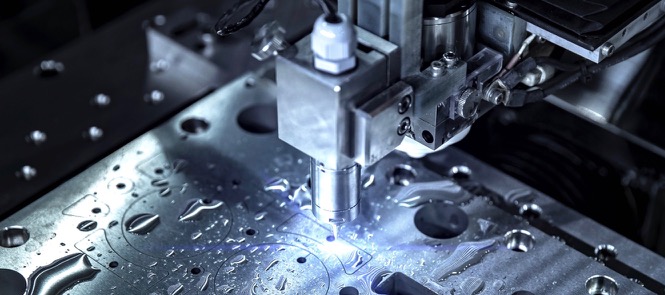

When people think of industrial cutting services, they tend to think of either saws with sharp serrated blades or lasers. However, at Precision Cutting Service, we use a different method: water jet cutting. Our process uses a computer guided, extremely thin, and high-speed jet of water, blasting at anywhere from 30,000 to 90,000 PSI depending on the application, which may also be enhanced with diamond dust or other abrasives for extra cutting power.

The result is one of the most flexible and useful of all cutting methods, with, perhaps, the highest degree of precision possible for any cutting requirement. Best of all, it's the most affordable of the industrial cutting methods. This makes it a great option for a wide variety of customers looking for cutting services.

Three Big Reasons to Use Our Water Jet Cutting Service

- Flexibility

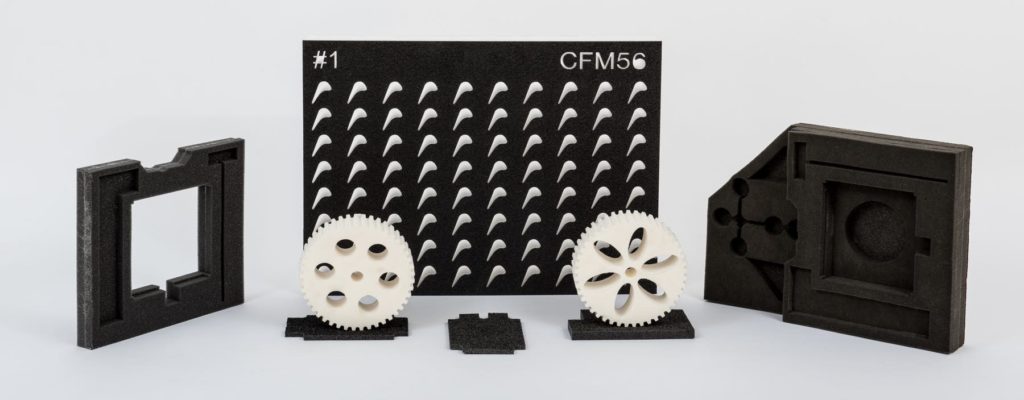

Water jet cutting can cut almost anything, including materials that other cutting methods can't handle. Unlike with blades and often with lasers, there are no ragged edges or damaged material in need of post-cutting rework. Water jet cutting leaves a smooth edge everytime. Also, unlike lasers, there's no heat damage to the material being cut, nor is there any possibility of altering the chemical composition of the material. And, no, the items being cut are never damaged by water. The water jets are simply moving too fast and are too precise to saturate the material.

In short, water jet cutting can efficiently and effectively cut materials as soft as foam or as hard as granite.

- Precision

Our water jet cutting systems achieve tolerances up to 0.003,” which exceeds the requirements of most applications and allows the cut end pieces to fit tightly together when necessary, as in complicated floor or wall medallions. Plus, this precision is achieved on virtually any material being cut.

- Low Cost

For our customers, the biggest benefit of all may be the cost savings. Water jet cutting is almost always the most inexpensive option for cutting services. After all, it really is just water, and it is incredibly fast. Also, because our systems are so precise, product can be tightly nested together, yielding more parts from the material being cut than can be achieved with other cutting methods. Additionally, because water jet cutting makes perfectly smooth cuts every time, refinishing, such as sanding, is never needed, saving even more money.

Precision Cutting Services

Water jet cutting is fast, precise, and cost-effective. That's why we're proud to be one of the top cutting services in the country. When you need material cut, and you're looking to save time and money, contact our team at Precision Cutting Service to make it happen.