Generally, people think of saws when they think about cutting something.However, when the application involves cutting an intricate design or shape, there’s a better, more precise and more economical option that can handle a huge range requirements:water jet cutting services.

How Water Jet Cutting Services Work

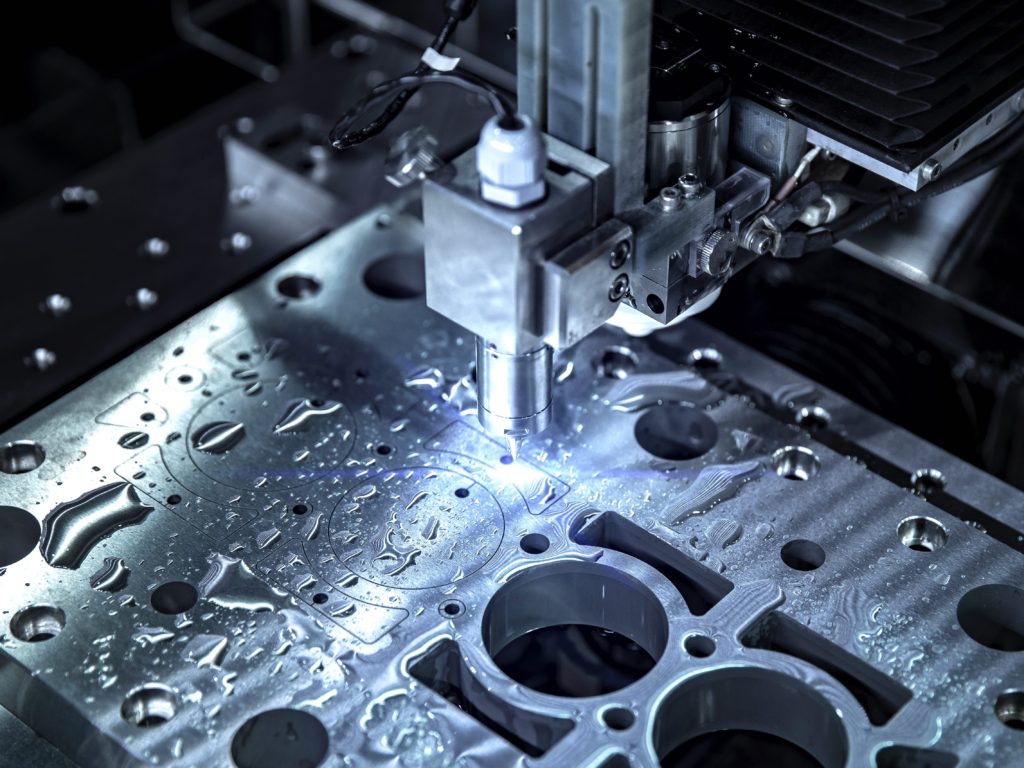

You might not think of water as being a good cutting tool, but we’re not talking about water from a hose. Water jet cutting systems use super high-pressure water streams between 30,000 – 90,000 PSI, sometimes with fine abrasives mixed in the stream, to achieve their cuts.

Basically, they can cut through nearly any material like a hot knife through butter, but with crisper results. And in the process, they offer clear advantages over other industrial cutting options:

- A smooth cut every time

Water jets don’t need second passes, and they don’t need rework; that is, post cutting finishing, like sanding, is not required. They create a perfectly smooth cut on the first pass, and without wasting much material either. This can significantly lower the cost and increase the speed of cutting.

- A huge range of material options

From a service standpoint, one of the biggest benefits of water jet cutting is that it can handle a vast variety of materials, more so than other cutting systems. Water jets can slice through stone and metal with ease, and they can also be used quite effectively on much more delicate materials, such as foam, rubber or acrylics.

Plus, there’s no risk of them damaging or altering the chemical composition of the material to be cut, unlike lasers, for example, that can burn, melt or otherwise stress the material they cut.

Are There Limitations to Water Jet Cutting Services?

Very few! At Precision Cutting Service we like to say that our only limitation is your imagination. Our water jet cutting systems can handle materials up to 8″ thick in sizes as small or smaller than a dime and as large as 6’ x 12’ with tolerances of up to ± .003 inches.

Unless you need something beyond those dimensions or tolerances, there really are no significant limitations to water jet cutting. It’s fast, it’s easy, and it’s almost always more affordable than cutting with saws or lasers. And we can work from designs sketched onto a napkin, or on the back of an envelope, or from a blueprint, or created in any of the popular digital file formats, such as eps, ai, psd, pdf, dxf or dwg, jpg, png, etc. (We prefer pdf,dxf or dwg, however.)

See the Advantages of Water Jet Cutting for Yourself with Precision Cutting Service.

Precision Cutting Service is a national leader in the use of water jet cutting services. We can create custom signage, floor medallions, gaskets, even furniture. Contact us to discuss what our water jet cutting systems can do for you.