The rule of thumb when ordering custom gaskets is to know their TEMP; that is, Temperature, Environment, Media, and Pressure. Those are the four most crucial aspects to consider when making gaskets because they are what determine the physical properties of the gasket necessary for proper functioning. With the TEMP information in hand, your custom gasket service should be able to produce the perfect gasket for the application.

At least, that’s the theory.

The situation becomes more complicated when you start looking at unusual applications, where the TEMP specifications go well beyond expected operating parameters. Sometimes engineers “overthink” a gasket’s operating conditions, and this can lead to unnecessary expense, or even compromised performance.

Why Preparing for Every Eventuality Isn’t Always the Best Idea When Ordering Custom Gaskets

So, let’s say you have an application where, in normal usage, a simple rubber gasket will suffice. But the engineer, fearing an occasional rogue extremely high temperature, specifies a more heat-resistant silicone gasket, which is much more expensive, to take the extreme heat.

Is the probability of a temperature spike really so high that it’s worth the considerable expense to upgrade all the gaskets?

Even then, what about performance under normal operating conditions? Sometimes basic materials are simply better at basic applications.

We advise our customers to identify the probability of outlier conditions and to assess the consequences of gasket failure. If it’s a situation where there’s a low likelihood of extreme variation in TEMP metrics, and where a gasket failure isn’t going to cause catastrophic and/or life-threatening harm, it may be better to go with the solution that addresses the most probable range of conditions.

Use Precision Cutting Service for Affordable, Expertly Made Custom Gaskets

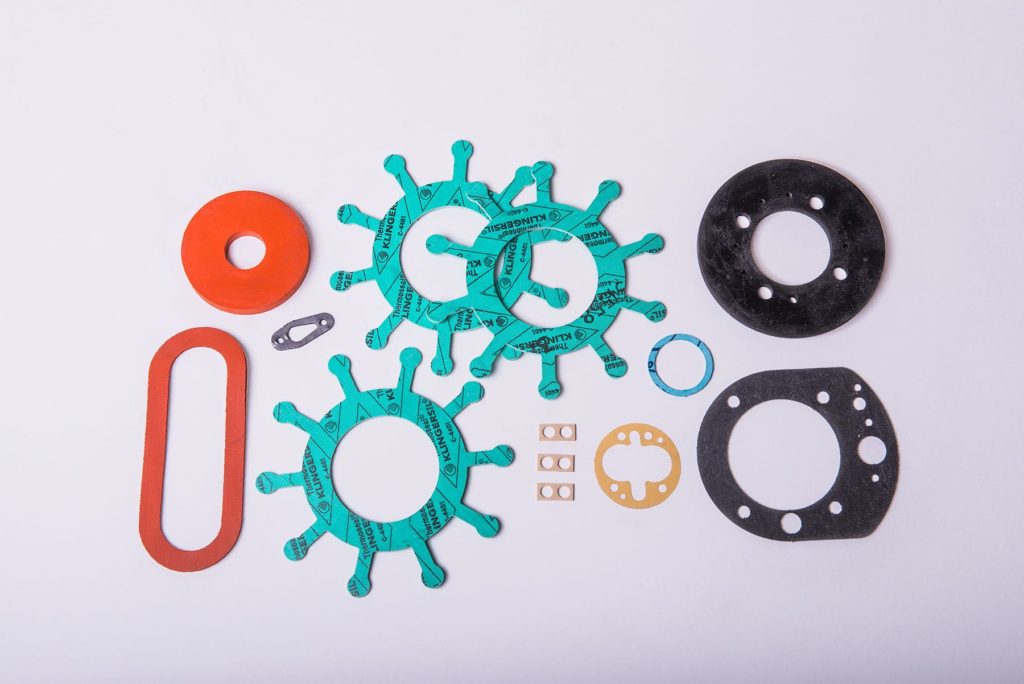

For more than 25 years, we’ve been leaders in the use of water jet cutting systems to create custom gaskets of all shapes and sizes. We work with a wide range of materials, including materials that other cutting systems struggle to handle. Combine that with our years of experience and you have a gasket supplier that can handle your every need.

Contact us to discuss the seals on your next project.