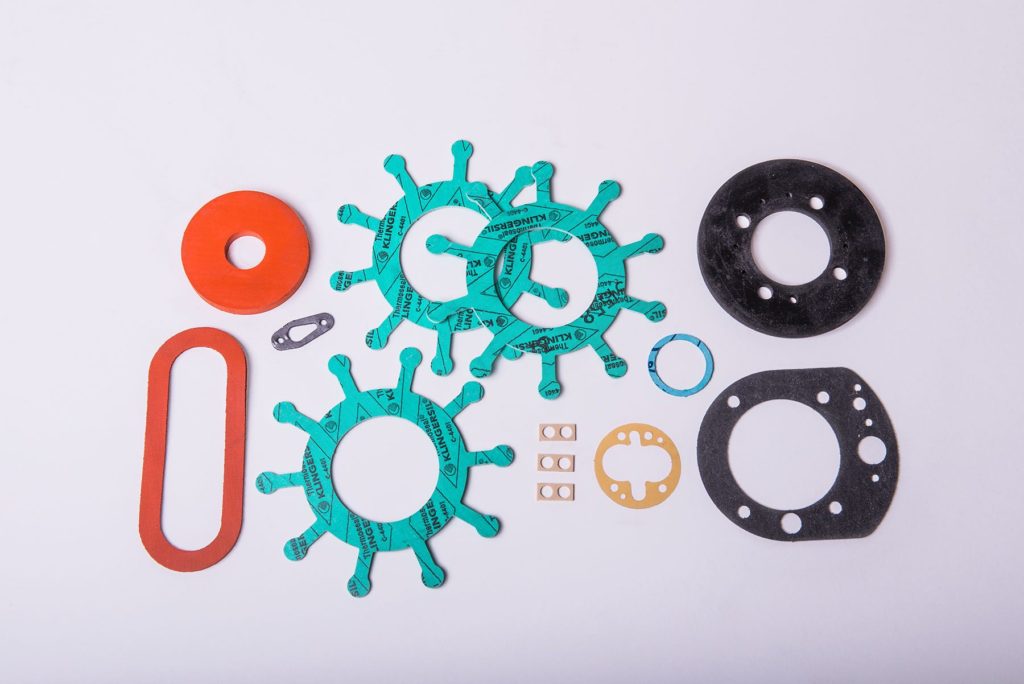

When creating a new product or sourcing replacement parts for older mission-critical hardware, custom gaskets can be a lifesaver. A quality custom gasket service can produce any number of gaskets to meet your needs, and they have a huge range of materials to choose from. This is what makes custom gasket orders so effective—unlike off-the-shelf gaskets, custom jobs can be fine-tuned to your exact needs.

To help you choose the right material for the job, they need to know a few things about the mechanical application. This can be easily remembered as TEMP: the four most important factors that influence gasket performance.

The Four Factors That Determine the Material(s) For Your Custom Gaskets

1. Temperature

The temperatures a gasket will need to withstand are a critical factor in deciding what material to use. Each gasket material has different operating ranges and will behave differently at various temperatures. For example, EPDM is good for low-temperature use (stable at -70°F), but it does not perform well at high temperatures. For high temps, you might want Silicone or Teflon.

So, it’s crucial to know the expected operating temperatures of your application.

2. Environment

Environment can be taken to mean “atmosphere,” but it can also include other environmental factors, such as exposure to sunlight / UV. Basically, where will the gasket be used? What external factors and chemicals will it be exposed to? The more of these that can be determined, the more reliable the resulting custom gasket will be.

3. Medium

Medium refers specifically to the materials the gasket will be coming into direct contact with. This would be the materials on either side of the gasket, as well as whether it will be in contact with water, oils, etc. This is vital because gasket materials don’t always interact well with various substances. For example, oil will break down natural rubber. A nitrile-based gasket is needed for oils.

4. Pressure

Finally, what will be the operating pressure of the gasket? This needs to include both the minimum and maximum expected pressures. Certain materials will be compromised if they undergo large ranges of compression and expansion.

Precision Cutting Service Can Be Your Custom Gasket Source

Whatever your needs, Precision Cutting Services has the capability to produce the custom gaskets you require, at a price your budget can handle. Contact us for a full consultation on your options!