Food safety is the key driver for the food processing industry. Food businesses must ensure that their food processing systems are flawlessly hygienic and, to help achieve this, they often need specialized food-grade gaskets.

Food processing gasket manufacturers, in turn, are required by law to conform to USDA and FDA guidelines so as not to contaminate food and beverages with their products.

When choosing a custom gasket manufacturer for your food processing application, consider factors such as manufacturer reputation, gasket design, material, and FDA and USDA compliance. Precision Cutting Service in Savannah, Georgia, is one of the nation’s leading food processing gasket manufacturers.

With more than 25 years of experience, we use sophisticated waterjet cutting systems to produce precise, reliable, burr-free gaskets that are guaranteed to meet all of your food processing requirements. If you are unsure of the gasket material you need, or if you are looking for alternatives, contact our team of skilled associates and we will offer solutions specifically tailored to your application(s).

Design

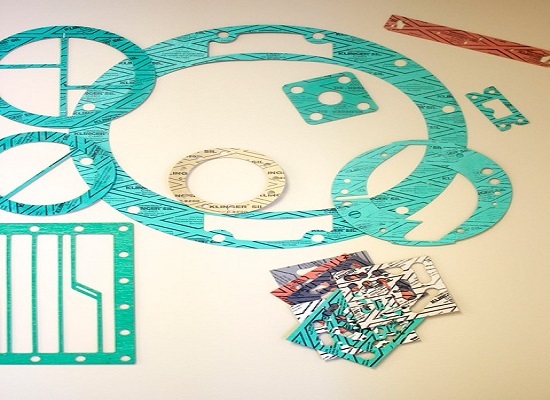

Food processing operations need their gaskets to fit and perform perfectly. Our modern computer design and waterjet cutting systems enable us to create accurate, high-performing food processing gaskets for every food processing application that requires them. Our waterjet cutting systems are equipped with robotically controlled cutting nozzles that operate at pressures up to 60,000 psi to produce precise, smooth gaskets with superior edge quality. These systems keep waste to the minimum by tightly nesting the gaskets to be cut into the material required, thus eliminating unnecessary material costs.

We will produce your gaskets from either CAD or PDF files, blueprints, or other technical drawings, or even from an actual gasket that you need to replicate or redesign. Also, if you need a prototype, we will make it quickly with no hassle.

Material

When selecting a material for your custom food processing gaskets, remember to consider temperature and pressure. A food processing gasket needs to handle both first and foremost. The gasket material also needs to be non-toxic to ensure the integrity of the final product, and our inhouse experts will see to it that it is.

Some commonly used gasket materials include non-asbestos fiber, white Nitrile Buna-N, silicone rubber, Teflon, PTFE, and EPDM rubber. Non-asbestos fiber and silicone rubber work best for high-temperature and/or high-pressure environments, white Nitrile Buna-N is good for abrasion and oily foods resistance, and PTFE works well for applications that use chemicals. EPDM rubber also works well for a variety of beverage applications. If you need guidance on the material that works best for your application, ask our proven customer service team for recommendations.

Compliance

Contaminated food is not a good thing, which is why strict compliance with all regulations is critical. At Precision Cutting Service we work hard to make certain the food-grade gaskets we furnish conform to all USDA and FDA guidelines and can be used in a wide variety of applications, including meat, poultry, and fish processing.

Reputation

Verifying a custom food gasket manufacturer’s reputation is one of the most important considerations for selecting a gasket manufacturer. Look for background and when appropriate ask for references. You will find Precision Cutting Service is blemish free with a reputation for reliability, dependable quality, friendly service, competitive pricing, and prompt delivery. Indeed, we know a thing or two about this business, having produced hundreds of thousands of gaskets since our inception. You can be assured we have the know-how and are equipped to tailor unique solutions to your operation.

Over the years, Precision Cutting Service has furnished gaskets to dairies, distilleries, breweries, bottling companies, food processing plants, food machinery manufacturers, and numerous food packaging operations. We would be honored to do the same for you. Contact us today via our online form or call (912) 233-9550 to request a quote!