Precision Cutting Service has been in the waterjet cutting business for more than 25 years and during this time we have heard our share of concerns about waterjet cutting’s capabilities. Most, if not all, were unfounded. Indeed, today, water jet cutting is one of the most sought after cutting methods by business and industry. Work still needs to be done, however, to spread awareness about waterjet cutting’s capabilities. Read on as we address four common misconceptions about waterjet cutting’s perceived limitations.

As industry veterans, we’ve used our waterjet cutting systems to cut and fabricate thousands of top-quality parts and assemblies from a wide range of materials and in a multitude of different sizes and shapes. Having worked with gasket manufacturers, machine shops, furniture designers, aerospace engineers, corporate purchasing departments, graphic artists, and architects, to name a few, our water jet cutting service offers sharp, competitive pricing, comprehensive design and fabrication capabilities, and rapid and timely delivery—all by efficiently producing incredibly precise and smooth cuts to tolerances of .003±.”

Myth #1—Waterjet Can Only Cut a Few Different Materials

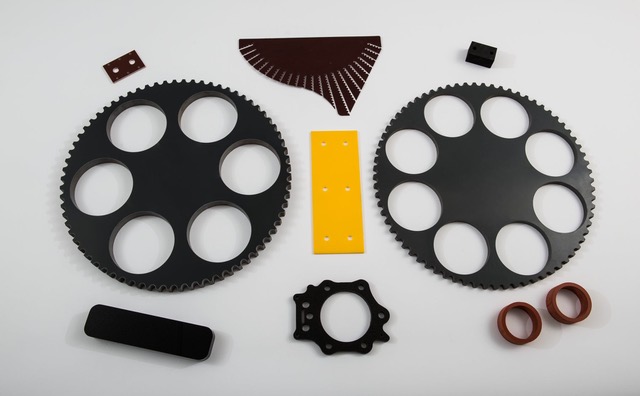

Waterjet cutting can accommodate a diverse range of materials, including, but not limited to, metals, plastics, stone, glass, ceramic, foam and composites. Waterjet cutting will easily cut through these materials without harming them, unlike laser cutting, that can damage many materials. Because it doesn’t have heat-affected zones or leave rough edges, waterjet cutting eliminates the need for secondary finishing, like sanding and filing, saving you both time and money. If you aren’t sure about what material will work best for you, get in touch and we will share our recommendations.

Myth #2—Waterjet Cutting Isn’t Accurate Enough to Cut Intricate Parts

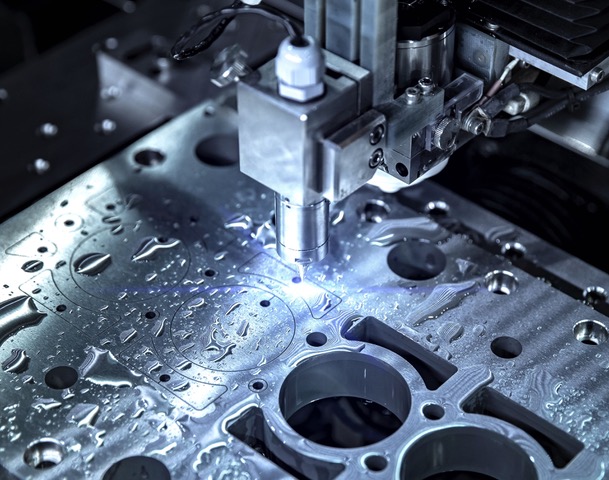

As indicated above, waterjet cutting systems are capable of tight tolerances because they use highly pressurized, extremely thin jets of water to slice smoothly through the material they have been assigned to cut. Whether you need a prototype for research, a finished part for your factory, or a large dimensional sign for your building, Precision Cutting Service can easily produce them and more. Because our cutting nozzles are computer controlled (aka, CNC), we feed the exact dimensions of the item(s) you need into our computers to produce the perfectly finished part you need. Simply furnish us with a CAD or PDF file, vector graphic, blue print, sketch or the physical part you need to replicate and we’ll do the rest.

Myth #3—Waterjet Cutting Can Only Handle Small Scale Projects

In our more than 25 years of service, we have produced large products, small products and everything in-between. We’ve produced large volume orders, one-offs and, again, everything in-between. If you have questions about our capabilities in this regard, reach out to us at your convenience.

Myth #4—Waterjet Cutting Is Expensive

Waterjet cutting is quicker and often more accurate than other techniques and doesn’t require post finishing. Because our cutting nozzles are computer controlled, they can tightly nest parts into the material to be cut so than waste is minimized. And waterjet cutting is more energy-efficient than lasers and other cutting techniques. Consequently, water jet cutting saves you money and time. For decades, and nationwide, our waterjet cutting systems have proven they can meet just about any cutting challenge.

If you are looking for a reliable vendor that can provide the products and services you need, look first to Precision Cutting Service. We make ideas happen and specialize in OEM parts, metal fabrication, custom cut aluminum signs and floor medallions, gaskets of all shapes and sizes, and custom cut stencils for the home, for business and industry, and for school and community playgrounds. Call us: (912) 233-9550 or contact us via our website.