Waterjet cutting technology is a powerful tool that boosts the efficiency and effectiveness of manufacturing firms in a multitude of industries. It is especially adept at improving lead times and reducing labor and material costs. This article explores five ways that waterjet cutting firms like Precision Cutting Service help manufacturers be the best they can be.

1. Reduced Material Waste

One of the biggest advantages of waterjet cutting technology is that it significantly reduces material waste. Other cutting methods, such as plasma cutting and laser cutting, generate a tremendous amount heat when cutting material, which often causes the composition of the material to change—in particular, melting and warping—which can render the parts they produce unusable.

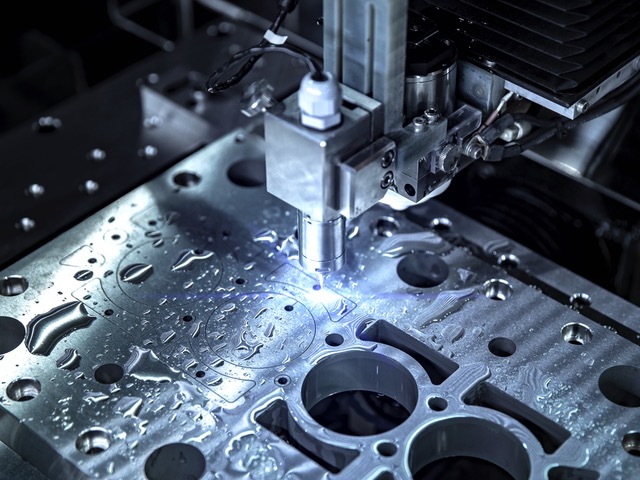

Waterjet cutting, on the other hand, uses an incredibly fine, high-pressure stream of cold water to cut through virtually any material without causing damage. It also is guided by sophisticated software that determines the best way to nest the parts that need to be cut from a sheet of material, thereby increasing yield and reducing material waste. Additionally, the edges of the parts it cuts are always perfectly smooth, which eliminates the need for labor intensive post finishing, such as filing, sanding or polishing.

2. Faster Cutting Speeds

Another advantage of waterjet cutting technology is that it cuts through materials much faster than traditional cutting methods. This is because the high-pressure stream of water it generates for cutting is more powerful and efficient that other cutting methods. And, as mentioned above, turnaround times are improved because post finishing labor is eliminated.

3. Lower Maintenance Costs

Waterjet cutting machines require less maintenance than traditional cutting machines. In short, they basically only require water, specially engineered cutting nozzles and a sophisticated software to produce the parts to be cut. Other cutting methods require far more costly maintenance to keep them in good working condition. The lower the maintenance, the lower the overhead and the lower the costs of production.

4. Versatility

Waterjet cutting technology is incredibly versatile and can cut through a wide range of materials, including plastic, rubber, composites, steel, aluminum, marble and more. Because every item it cuts can either be a standard or highly customized part, it is an ideal cutting method for many different industries, including aerospace, railroads, automotive, and medical device manufacturing. It is particularly well suited for dimensional sign manufacturers, petrochemical and food processing gasket users, flooring contractors, architects and interior designers in need of decorative floor medallions, and all manner of firms seeking unique and/or machine specific parts production.

5. Increased Precision

Waterjet cutting technology offers unparalleled precision compared to traditional cutting methods. It is this precision that also helps keep manufacturing costs down. Material waste is kept to minimums that other cutting methods are not capable of achieving.

Also, its precision is what makes waterjet cutting an excellent choice for producing complex and intricate designs. Its incredibly fine and sharp pressurized stream of cutting water is capable of cutting tolerances as tight as ± .003.” But this precision is not just excellent for intricate projects. It is also perfect for quickly and accurately producing routine jobs as well, such as large volumes of industry specific gaskets.

Founded in 1994, Precision Cutting Service is one of the nation’s most trusted waterjet cutting firms. Their modern waterjet cutting systems and skilled staff help hundreds of companies each year reduce their manufacturing costs by delivering reliably efficient and effective cutting solutions.

To learn more, contact Precision Cutting Service today. Dial 912-233-9550, email sales@precisioncuttingservice.com, or use their convenient online quote form: https://precisioncuttingservice.com/request-a-quote/.