When it comes to manufacturing aircraft components, precision is critical. Any error, no matter how slight, can lead to catastrophic consequences. This is why the aerospace industry must always use proven technologies to manufacture its component parts.

Waterjet cutting is one such method, and Precision Cutting Service is one of the nation’s leading waterjet cutting firms. For more than 29 years, they have consistently produced thousands of extraordinarily precise and dependable parts for the aerospace industry. And they do so for other industries, too, including automotive, marine, transportation and food processing, among others.

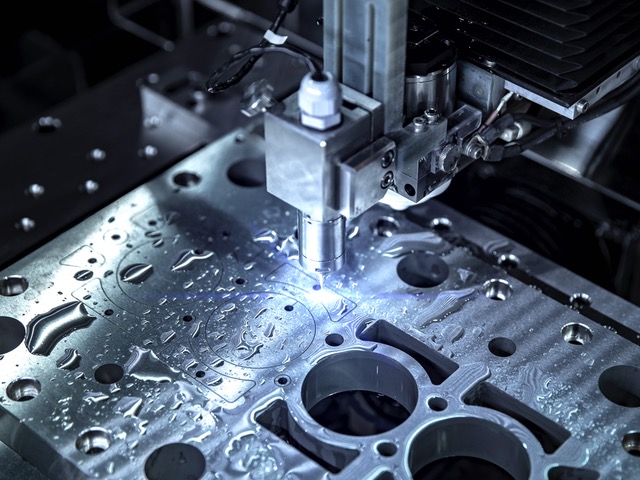

With tolerances of ± .003,” Precision Cutting Service’s waterjet cutting systems use a fine, highly-pressurized and incredibly sharp stream of water to cut a wide range of materials, including stainless steel, aluminium, titanium, composites, plastics, rubber, marble and more. They routinely cut intricate designs, complex parts and routine shapes with a high degree of precision. Indeed, they are exactly the type of proven resource the aerospace industry needs.

Here’s why:

1. Precision

As mentioned earlier, their cutting tolerances are ±.003,” which means there is never a variation in size or thickness, and all the parts they make fit and function as designed. Each component part is cut to exact specifications and there are never any irregular edges. Every part is smooth and free of defects, ensuring optimal fit, performance and safety.

2. Versatility

The aerospace industry requires components made from a variety of materials, including, as mentioned above, stainless steel, aluminium, titanium, composites, plastics, rubber and more. Precision Cutting Service’s waterjet cutting systems effortlessly cut these materials in thicknesses up to 6” and lengths up to 12’ to produce the parts their aerospace customers require.

3. Reduced Material Waste

Traditional cutting methods often produce significant amounts of wasted material that increase manufacturing lead-times and costs. This is because the blades they use or the heat they generate sometimes destroy edges or alter the chemical composition of the material they are cutting. Also, because conventional cutting systems cannot nest products as tightly as Precision Cutting Service’s waterjet cutting systems can, they typically use more material than necessary.

4. Time-Saving

The aerospace industry is fast-paced and tends to require quick or on-demand turnaround times. Waterjet cutting systems, partly because they are driven by powerful software and computers, cut faster than conventional cutting methods. Additionally, they do not require tool changes, which further reduces production times. Best, the staff at Precision Cutting Service understands the need for speed and, with their experience and capable technology, makes certain their aerospace customers receive their parts when or before they need them.

5. Cost-Effective

In sum, waterjet cutting systems are simultaneously efficient and effective, saving time and money in both the near term and long run. Plus, waterjet cutting is precise, virtually eliminating the possibility of a catastrophic error.

To learn how your firm can improve quality, enhance safety and save money by engaging the services of a waterjet cutting company, contact Precision Cutting Service online, or give us a phone call (912-233-9550), or send us an email (sales@precisioncuttingservice.com) with your questions or specifications. We will respond promptly and you will be pleased with the solutions we offer.