OEM (Original Equipment Manufacturer) parts are custom-made replacement compnents for specific machines—for example, conveyors, cranes, tractors, elevators or compactors. They’re availability is critically important to keep equipment running when an original machine part wears down or breaks.

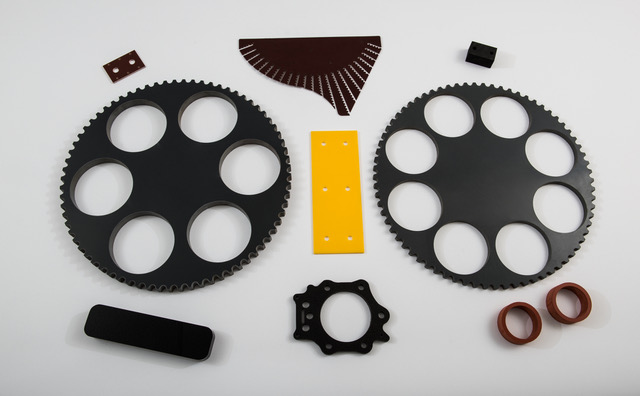

Many people think of auto parts when they see the term, OEM, but OEM more broadly applies to all manner of machine parts. Wheel bearings, knife blades, brackets, gaskets, press plates, splash guards and gears are just a few examples of machine parts that periodically need to be replaced.

There are numerous occasions when an original equipment manufacturer cannot provide a specific replacement part, most likely because they no longer support it. When this happens, equipment owners need to turn to a custom OEM parts manufacturer to avoid production downtime.

Precision Cutting Service is a proven custom OEM parts manufacturer. For more than 25 years, we have dependably furnished custom OEM parts nationwide to businesses, factories, job sites and institutions. Our seasoned professionals provide end-to-end service—from concept to delivery—to take care of your OEM replacement parts requirements. If you are looking for an OEM parts manufacturer that can produce superior quality parts with excellent customer service and competitive pricing, look no further than Precision Cutting Service. Our technical expertise and extensive portfolio make us the stress-free choice for the OEM parts you need.

Using Waterjet Cutting Technology for Fabricating OEM Parts

We use advanced waterjet cutting machines to scan, engineer and produce replacement parts. With their computer controlled cutting nozzles, our machines operate at pressures up to 60,000 psi and make precise, burr-free cuts that do not require post-cutting finishing, like sanding, which saves you time and money. They also achieve tolerances of .003”± to make certain your replacement parts fit properly.

The capabilities of our waterjet cutting systems make Precision Cutting Service one of the fastest, cleanest and the most cost-effective OEM parts manufacturers in the country. The industries we’ve served include marine, automotive, agriculture, food processing, health care, aerospace and mining, to name a few.

Working With All Kinds of Materials

Waterjet cutting is a cold process so the chance of changing the chemical composition of the material being cut is completely eliminated. This allows us to manufacture OEM parts from cork, rubber, plastic, Kevlar, steel, aluminum, foam core, and more. Also, we can cut material up to eight inches thick, in sizes as large as a full-size SUV and as small or smaller than a dime. In addition, our waterjet cutting systems enable us to cut geometrically complex designs that challenge other technologies. Indeed, we like to say, “Our only limitation is your imagination.”:

No matter the complexity, we can accommodate most needs. If post cutting assembly is required, our metal fabrication experts will be delighted to assist you with your requirements. Better, because we handle all the cutting, forming, powder coating, assembling, and welding, you only have to work with one vendor, saving you the time, expense and potential frustration of managing multiple vendors.

Get Started Today

Send us a sketch, drawing, blueprint, CAD file, PDF, or even the part you would want us to make. We’ll take it from there. Our service is reliable and our solutions are cost-effective, as our more than 1,000 repeat customers will attest. Call our team to discuss your OEM parts requirements for a swift response: (912) 233-9550. Or contact us online with specifics.