If you are wondering about the right cutting approach for your next metal fabrication project, please read on. When it comes to metal fabrication, waterjet cutting is the industry’s go-to cutting technique because of its its proven benefits over other cutting methods. Combine it with an expert operator and you get the best output at the best price.

For more than 25 years, Precision Cutting Service has been using waterjet cutting systems to fabricate top-quality products for our nationwide clients across industries that include aerospace, healthcare, transportation, mining, automotive and mining, among others. Our many testimonials vouch for the bebefits of doing business with us.

We make ideas happen by turning our clients’ visions into reality. We can help you, too. With virtually no limitations on materials or project complexity, our state-of-the-art waterjet cutting systems enable us to fulfill all your unique needs. And when you work with us, one of the country’s leading waterjet cutting companies, you will enjoy quality workmanship. timely delivery and the best pricing.

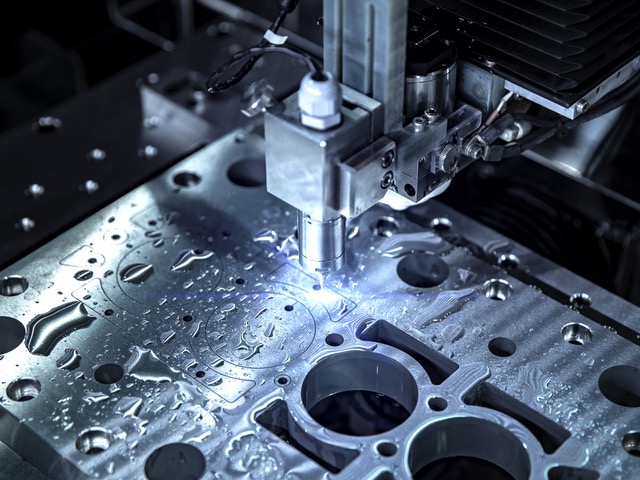

Using computer-controlled nozzles and a high-pressure stream of water (sometimes mixed with fine abrasives), waterjet cutting can cut a wide variety of materials to produce products for a variety of applications, yielding cleaner results and eliminating thermal distortion or rough edges. Follow along as we discuss its benefits in detail:

Extensive Material Selection

Whatever material your project requires—for example, steel, aluminum, titanium, iron, copper, brass, glass, granite, ceramic, or composites—our waterjet cutting systems can use them to cut straight-forward up to geometrically complex designs with amazing precision.

You can either supply us with the material you need, choose from our comprehensive inventory, or ask us to source your material from one of trusted vendors. Either way, you can count on us to cut and fabricate the part or assembly your need. We’re your one-stop-shop for your metal fabrication needs. Simply send us your requirements and we’ll do the rest. We can work from CAD files, blueprints, mechanical drawings, sketches or even the worn or broken part or assembly your need to replace.

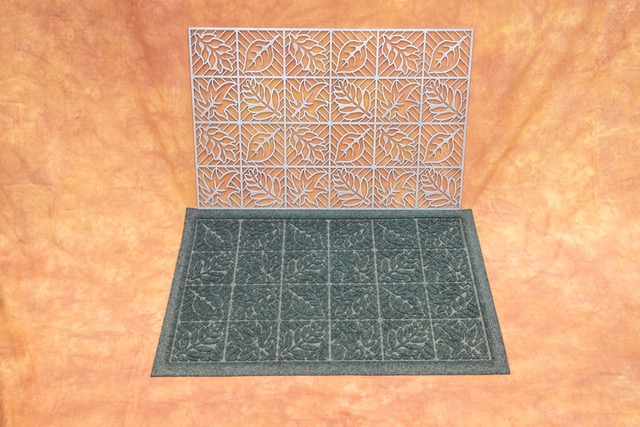

Smooth Finishes

With computer-controlled cutting heads operating at pressures up to 60,000 psi, our waterjet cutting systems produce incredibly smooth, burr-free cuts that eliminate the need for secondary finishing, such as sanding, filing or polishing. Moreover, they achieve tolerances of ±.003,” which makes certain the products we cut are precise, fit as designed and perform as expected. In short, the dependability of the products we cut and fabricate are unmatched when compared to other cutting technologies that are prone to leave blemishes and other distortions that require post-cutting attention, extra expense and often delays.

No Distortion

High temperatures from laser or plasma cutting technologies often result in Heat Affected Zones (HAZ), chemical and/or structural material distortions that need to be fixed, if possible, before the product can be delivered. Because waterjet cutting uses only water, HAZ distortions— burning, melting, warping, or cracking, for example—never occur.

Cost-effective

Another benefit of waterjet cutting is its advanced part nesting capabilities that minimize material waste and reduce costs. The software that drives our waterjet cutting systems achieves these savings by optimizing cutting layouts to maximize the number of parts that can be cut from a material’s size.

Whether you need a one-off simple assembly or require multiple components throughout the year, look no further than Precision Cutting Service. To learn more, Contact us online, request a quote or give us a phone call (912-233-9550) today.