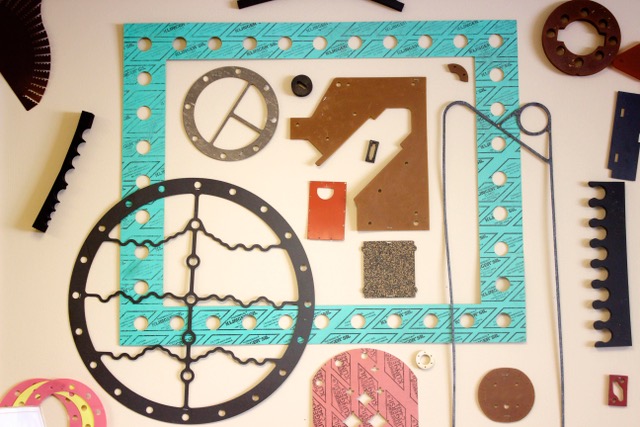

Industrial gaskets, when made correctly, create reliable seals between two surfaces to keep equipment operating safely and productively. They come in a variety of materials and offer unique benefits to suit specific purposes and conditions.

Founded in 1994, Precision Cutting Service is one of the nation’s most trusted industrial gasket manufacturers. The people there, better than most, know what materials best perform in virtually every industrial application that requires a seal. They are also the leading experts at efficiently and effectively producing gaskets to help industrial firms operate at optimum levels.

This discussion is a brief overview of the different types of industrial gasket materials and the various business sectors that use them.

Graphite Gaskets

Graphic gaskets provide excellent thermal conductivity, chemical resistance and low creep relaxation (elasticity loss). They are also particularly good for high temperature, high-pressure applications, such as those found in refineries, petrochemical plants and power generation stations.

PTFE Gaskets

PTFE (Polytetrafluoroethylene), also known as Teflon®, is an effective gasket material for industries that deal with corrosive chemicals and/or extreme temperature fluctuations. They are commonly used in chemical processing, pharmaceuticals, and food manufacturing.

Non-Asbestos Gaskets

Non-asbestos gaskets, as one might surmise, eliminate the health risks associated with traditional asbestos gaskets. They are made from synthetic fibers, such as rubber, graphite, or PTFE.

Rubber Gaskets

Rubber gasket material comes in various elastomers, like Nitrile, EPDM, Silicone, and Neoprene. Each offers their own unique benefits.

Nitrile is resistant to oil. EPDM is ideal for O-ring and water gaskets. Silicone is good for high temperatures and Neoprene provides excellent resistance to oil, ozone, and oxidation and is prevalent in petrochemical operations.

Metal Gaskets

Metal gaskets are usually made from copper, brass, aluminum, and stainless steel. Copper gaskets, for example, are used in vacuum systems. Brass gaskets are often found in pipe fitting and seal applications. Aluminum gaskets are perfect for the automotive industry, among others, where intricate shapes are required that won’t break or weaken, and stainless steel is a reliable gasket material for corrosive environments and where the gaskets must absorb a tremendous amount stress and vibration.

To learn more about industrial gasket manufacturing and how Precision Cutting Service can help your business, contact our knowledgeable and friendly customer service staff today!

Feel free to call us at 912-233-9550 or email sales@precisioncuttingservice.com. You can also send us a quote request using the online form found on the home page of our website or use our Contact Us page to get in touch with one of our team leaders directly. Either way, you’ll receive a prompt, courteous and informed response that will help you find the solution you deserve.