Waterjet cutting is a highly beneficial and widely used method for cutting various materials. Frankly, it is one of the most popular, most reliable cutting technologies for good reason.

Read on to learn why industries like aerospace, automotive, electronics, transportation, marine, healthcare, construction and more others depend on waterjet cutting firms like Precision Cutting Service to support their operations.

Versatility and Adaptability

Waterjet cutting offers significant benefits because it effectively cuts a wide range of materials, such as stainless steel, titanium, aluminum, ceramics, composites, stone, glass, and more.

Whether businesses require cutting intricate automotive parts, precise architectural components, or delicate decorative pieces, waterjet cutting can handle these tasks economically, dependably and proficiently.

Its versatility allows businesses to outsource their precision cutting needs to a single firm like Precision Cutting Service. As a result, turnaround time is shortened, accuracy is improved, costs are reduced and the hassles associated with managing numerous vendors are eliminated.

Boost Efficiency and Productivity

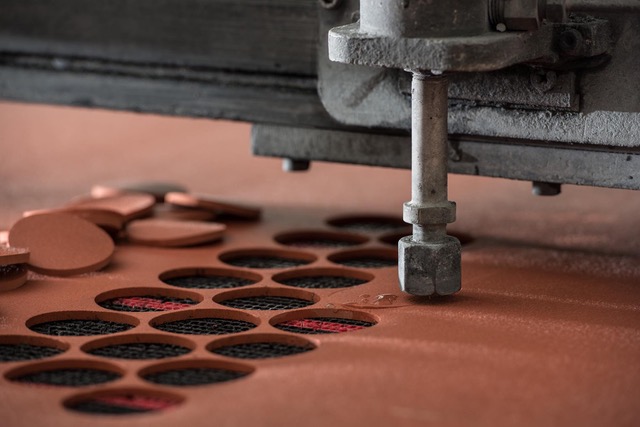

Waterjet cutting uses a fine, highly pressurized steam of water to make its cuts expeditiously. This stream is driven by sophisticated software through a system specific nozzle to ensure precision, maximize material yield and promote cutting speed. Each cut is smooth and exact, eliminating the need for post finishing like sanding, filing or polishing.

As a result, waterjet cutting enables businesses to get more parts from their material, faster, more precise and ready to ship than other cutting technologies.

Cold-Cutting Process

It is worth noting that waterjet cutting is a cold-cutting process. This means that it doesn’t generate heat while cutting material, making it suitable for heat-sensitive materials like plastics, composites, and food products, where thermal distortion is a concern. In fact, waterjet cutting preserves the integrity of the material it cuts so that manufacturers can depend on receiving the exact product they ordered, not one that is chemically or structurally altered.

To learn more about how waterjet cutting can help you and your business, contact our resourceful and friendly customer service staff today! Send us a note via our Contact Us website page, call 912-233-9550, or send us a quote request using our online form.